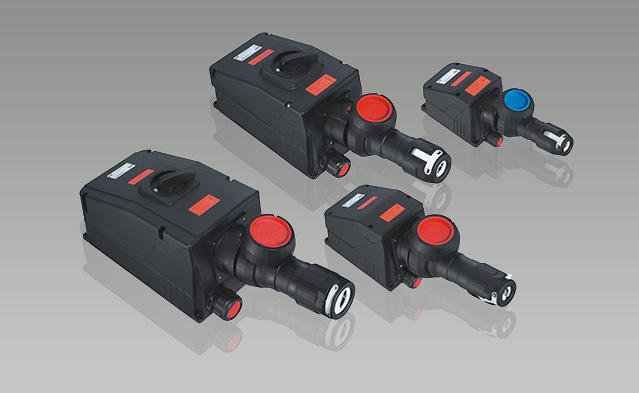

Product Introduction: Explosion-proof electrical boxes are used in potentially explosive atmospheres (zones 1 and 2, 21 and 22) and harsh working hazardous areas. It has high corrosion resistance, waterproof and dustproof characteristics, which can meet the chemical, petroleum and offshore industries. Requirements for use. It has high and low temperature resistance (from -55℃ to +95℃ (stainless steel box 115℃)), high protection degree (IP66), suitable for most hazardous gas locations (temperature group from T6 to T4), and meets the latest international explosion-proof standards, etc. characteristic. The explosion-proof electrical box includes explosion-proof junction box, explosion-proof control box, explosion-proof socket box, explosion-proof distribution box, etc. The enclosure has a variety of standard sizes to choose from, and special sizes can also be customised according to customers' needs. The explosion-proof electrical box can be equipped with explosion-proof pushbuttons, explosion-proof signal lamps, explosion-proof ammeters, explosion-proof voltmeters and other explosion-proof components according to customers' requirements. In addition, the box body, installation accessories and internal components of this series of explosion-proof electrical boxes all have independently certified international explosion-proof certificates, forming multiple protection with enhanced safety protection shells. Product Model: CZ12 series all-plastic explosion-proof electrical box and CZ13□□ series stainless steel explosion-proof electrical box, including explosion-proof junction box, control box, socket box, distribution box, bus box, various switches/circuit breakers, etc. Selection scheme: According to customers' requirements, freely select the specifications, quantity, rated parameters, etc. of the components; LCL scheme: multiple single boxes can be connected into a whole.

Product Material: CZ12□□ series all-plastic explosion-proof box, the box body is made of high-strength, anti-static SMC material, pressed by a mould, anti-shock, fire-proof, crash-proof, anti-UV, protection against acid, alkali, salt, oil, etc.. Excellent ability, more than 20 years of practice, all over Russia, Europe, Middle East, Asia-Pacific, South America and other climate tests. CZ13□□ series stainless steel explosion-proof box. The box body is made of 304, 316L and other stainless steel materials. It is manufactured by laser cutting, CNC bending, robot welding, surface drawing and other processes. It not only has good corrosion resistance, but also has accurate box size. Excellent processing and beautiful appearance. Exquisite structure: door opening and lid opening: the hinged design is adopted between the body cover, and the user can choose an open-lid or open-door structure according to the needs of installation, wiring and maintenance; an operation window is installed on the box cover, and the user can conveniently carry out the on-site operation; free splicing: The unique concave-convex design of the box cover and the box body not only improves the overall structural strength of the box body, but also facilitates the seamless splicing of each box body; Overall protection: Automatic foaming can be used for different places of use in combination with the adhesive seal; Built-in components: All the company's current explosion-proof component modules, and other modules with Ex component certificates; Wiring terminals: Phoenix series terminals and other terminals with Ex component certificates. Excellent performance: the lowest ambient temperature: the lowest ambient temperature can reach -55℃ The highest ambient temperature: the highest ambient temperature can reach +95℃, Among them, the stainless steel box series can reach +115℃; Temperature group: according to the selected ambient temperature and total component power dissipation, temperature group up to T6; Protection degree: up to IP66; Rated voltage: up to 690V; Rated current: up to 630A; International certification: The boxes, installation accessories and internal components of this series of explosion-proof electrical boxes have independent certifications The international explosion-proof certificate, which forms multiple protection with the increased-safety protective shell; Explosion-proof type: This series of explosion-proof electrical boxes cover explosion-proof, encapsulation, increased safety, intrinsic safety, sand washing, light radiation, dust protection and other explosion-proof types; The latest ATEX/IECEx certification: This series of explosion-proof electrical boxes adopts the latest international/European explosion-proof standards, and the verification methods and test requirements are more reasonable and rigorous, representing the latest explosion-proof technology and safety concepts. A new level of safety: The current advanced maximum power dissipation method certification is adopted to optimise customer solutions and maximise product utilisation efficiency. 1) Ex component modules can be freely added, which greatly expands the range of customers' choice of functional components. 2) The rated electrical parameters can be flexibly set, so that the user's programme design is not restricted by the parameter specifications. 3) Very wide applicable environmental range: from -55°C to +95°C (stainless steel box 115°C); 4) Temperature group does not go from T6 to T4, suitable for most hazardous gas locations; 5) Free splicing of multiple cabinets, the customer's functional design of the explosion-proof cabinet is not limited by space and can be expanded indefinitely; 6) By adjusting the power dissipation in the cabinet, individual excessive component parameters are forced to choose a larger cabinet, which causes a waste of resources, to ensure that the space and internal components of the explosion-proof cabinet are used to the best; 7) The certificate covers a wide area and the effect is immediate, without the need for changes in design schemes and selected components It must be re-tested and certified to save the time of the customer's project from program design to equipment installation.

English

English 中文简体

中文简体