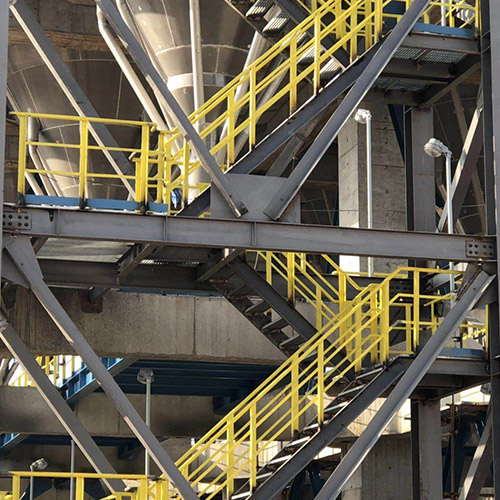

The challenges

·The altitude of the factory site is 2573~2615m which requires the products have good electrical insulation performance.

·Conditions like long sunshine time, high ultraviolet intensity, large temperature difference between day and night, low temperature in the area to -31.7℃ require products with good resistance to aging and low temperature performance;

· Equipments are non-intermittent operation systems that the product are required to have high reliability. Moreover, the on-site environment is relatively harsh and maintenance is inconvenient that the products are also required to have better maintainability;

Solutions

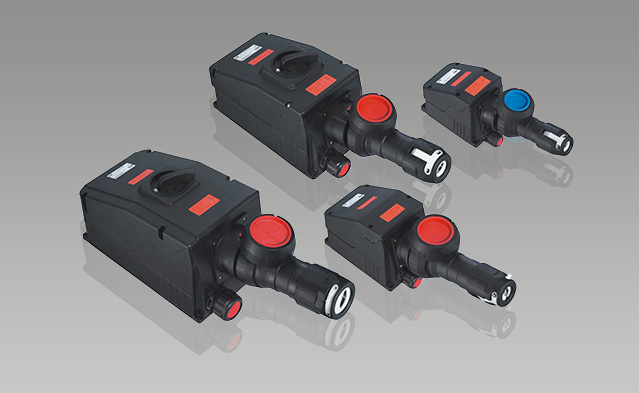

·CZ products meet the requirements of application in harsh environments, and can be operated stably for years even in extreme low temperature and strong ultraviolet radiation. Those products ensure the safety at site.

·The environments of high temperature, high corrosion, strong ultraviolet rays, strong wind and waves will affect the explosion-proof performance and application performance These conditions are unavoidable in deep-sea operations. CZ Company conducts product tests in strict accordance with the latest IECEx standards and ATEX standards, selects the international mainstream explosion-proof form, the compound explosion-proof form, and achieves high-protection explosion-proof products through the combination of built-in explosion-proof components with increased safety enclosures. So that electrical equipment has perfect comprehensive performance such as high temperature resistance, corrosion resistance, and UV resistance. The increased-safety enclosures’ material can be antistatic glass fiber reinforced polyester (GRP) or stainless steel 316L.

·CZ products adopt the design concept of easy installation, free-maintenance and low-cost maintenance, which greatly improves the safety of on-site application.

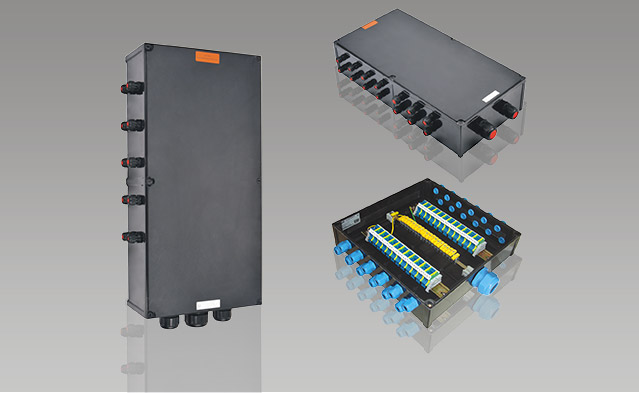

· CZ explosion-proof components adopt standardized, modular design, and have independent explosion-proof certification. On-site construction personnel can easily maintain it even without professional explosion-proof installation knowledge, which greatly improves the fault tolerance rate of on-site application.

Values for Customer

·The higher the altitude, the lower the air pressure. It will cause the breakdown voltage to drop as well as reduce the arc extinguishing performance of switches and other components, which will affect the on-off performance. According to related studies, the external insulation strength of electrical products decreases by about 8%-13% for every 1,000 meters of altitude. Therefore, explosion-proof electrical equipment used in high altitude areas will bring unpredictable risks to explosion protection. In order to meet the electrical and explosion-proof safety of the equipment used in the above high-altitude areas, CZ explosion-proof electrical and lighting products are designed and manufactured in strict accordance with the international IECEx and EU ATEX explosion-proof standards. The designed electrical clearances are higher than the low-voltage electrical standards, and adopt double insulation, strengthen insulation and other technologies to ensure that the insulation performance of the product meets the requirements for use in high altitude areas;

·High-intensity ultraviolet rays and high operating environment temperature will accelerate the aging of the equipment's non-metallic enclosure, while low temperature will reduce the impact resistance of the equipment and damage the IP protection capability of the equipment, bringing hidden risks to the long-term explosion-proof safety at site. In view of the above environment, CZ uses materials with excellent overall performances such as light aging resistance, high temperature resistance and low temperature resistance, and optimizes the structural strength of the product through the design method of finite element simulation analysis. Thus, the product can be operated with long-term safe to meet the harsh natural environment at the project site.

·The long-term non-intermittent operation of electrical equipment will aggravate the mechanical fatigue, tear and aging of product electrical performance, and reduce the reliability of the product. CZ has a complete quality management control system. It is the first company in the explosion-proof industry to implement IS09001 and ATEX quality management systems, and it is also one of the companies that implement the GJB90001 military standard quality control system. At the beginning of the design and development of new products, the company took reliability, safety, environmental adaptability, and maintainability as product quality goals. It adopted standardized and modular design, which not only ensured the products’ high reliability, high safety and high environmental adaptability but also made maintenance and replacement easier, solving the dilemma of customer site high altitude, low oxygen content, inconvenient inspection and maintenance.

English

English 中文简体

中文简体