The challenges

· Drilling platforms vibration, shock and other complex operating environments require the equipment to have perfect electrical performance and anti-vibration and impact resistance;

· Deep-sea operations, high temperature, high corrosion, strong ultraviolet, strong wind and waves and other marine environments require equipment to have perfect comprehensive performances such as high-temperature resistance, corrosion resistance, and light resistance;

· Deep-sea operations are difficult to maintain, and the equipment is required to be light and with high stability and super reliability;

Solutions

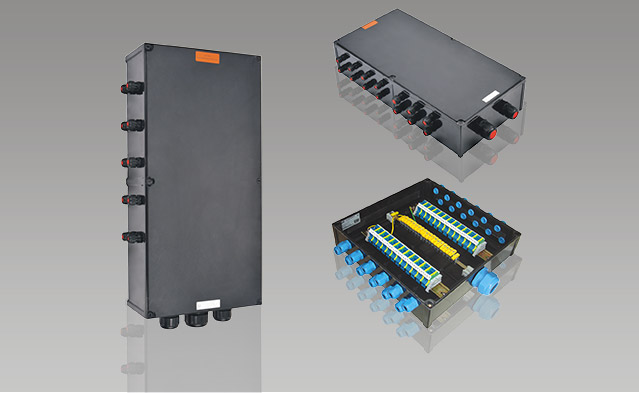

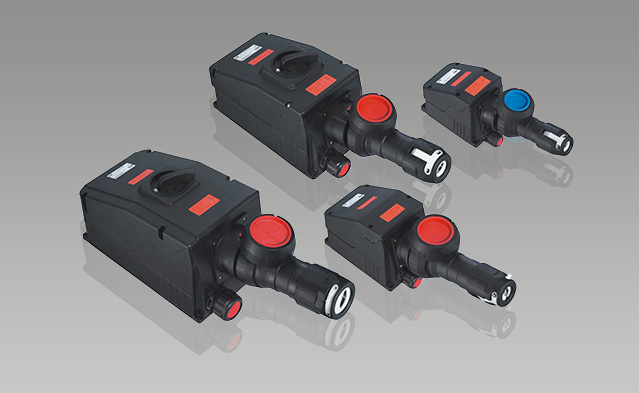

· Complicated work environment such as vibration and impact at site will affect the electrical connection, installation and fixation of electrical equipment, and damage the explosion-proof performance of explosion-proof equipment. In response to this complex operating environment, CZ Company chooses high-quality high- and low-temperature-resistant and impact-resistant raw materials and optimizes the structural design to solve the fundamental problems from the raw materials. Clamp nuts are often used in electrical equipment to reduce non-structural connections and enhance seismic performance.

· The environments of high temperature, high corrosion, strong ultraviolet rays, strong wind and waves will affect the explosion-proof performance and application performance These conditions are unavoidable in deep-sea operations. CZ Company conducts product tests in strict accordance with the latest IECEx standards and ATEX standards, selects the international mainstream explosion-proof form, the compound explosion-proof form, and achieves high-protection explosion-proof products through the combination of built-in explosion-proof components with increased safety enclosures. So that electrical equipment has perfect comprehensive performance such as high-temperature resistance, corrosion resistance, and UV resistance. The increased-safety enclosures’ material can be antistatic glass fiber reinforced polyester (GRP) or stainless steel 316L.

· Deep sea operations are difficult to install and maintain, and unstable products and non-reliable components will bring economic losses to users and potential safety risks. CZ has a complete quality management control system. It is the first company in the explosion-proof industry to implement IS09001 and ATEX quality management systems, and it is also one of the companies that implement the GJB90001 military standard quality control system. At the beginning of the design and development of new products, the company took reliability, safety, environmental adaptability, and maintainability as product quality goals. It adopted a standardized and modular design, which not only ensured the products’ high reliability, high safety and high environmental adaptability but also made maintenance and replacement easier, solving the dilemma of customer site high altitude, low oxygen content, inconvenient inspection and maintenance.

Values for Customer

· CZ products meet the requirements of the application in harsh environments and can be operated stably for years even in extremely low temperatures and strong ultraviolet radiation. Those products ensure the safety at the site.

· CZ products adopt the design concept of easy installation, free maintenance and low-cost maintenance, which greatly improves the safety of the on-site application.

· CZ explosion-proof components adopt standardized, modular design, and have independent explosion-proof certification. On-site construction personnel can easily maintain it even without professional explosion-proof installation knowledge, which greatly improves the fault tolerance rate of on-site application.

English

English 中文简体

中文简体